Automation Facilities

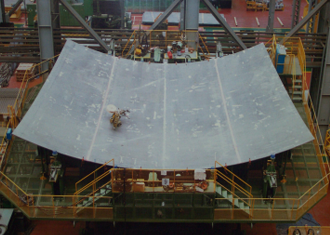

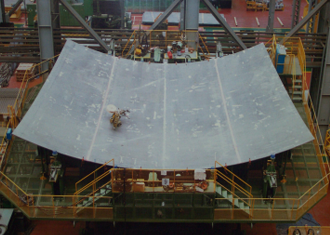

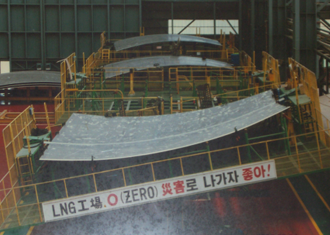

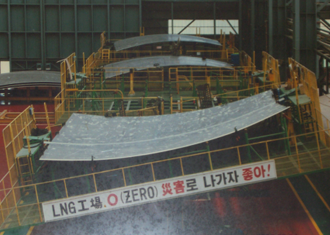

TILTING JIP FOR MANUFACTURING MOSS LNG TANK

Lng Tank Assembly

Lng Tank 4-Segment 용접용 Tilting Jig

Lng Tank 2-Segment 용접용 Tilting Jig

Facility Overview

This system is a tilting jig for High Current Mig welding of each 2, 4, 8-Segment of each Al Segment Plate of Trapezoid Type and Circle Type with 3D curvature during the manufacturing process of LNG Moss Spherical Tank. All work processes on the tilting jig are in order, conducting 2-Segment concave and convex welding, 4-Segment concave and convex welding, and finally 8-Segment concave and convex welding. Each equipment consists of Tilting Bed, Driving Unit, Fit-Up, Pipe Jig, Guide Unit, Rail Support, Hyd 'System, and Control System.

Equipment Composition

- Tilting Jig for Welding 2-Segment Concave Plate

- Tilting Jig for Welding 2-Segment Convex Plate

- Tilting Jig for Welding 4-Segment Concave Plate

- Tilting Jig for Welding 4 & 8-Segment Concave Plate

- Tilting Jig for Welding 4 & 8-Segment Convex Plate

- Tilting Jig for Welding E'Q 3-Segment Concave Plate

- Tilting Jig for Welding E'Q 3-Segment Convex Plate

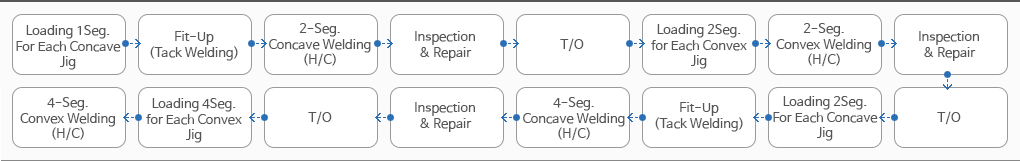

Manufacturing Process

Welding Technique

| No | Description | Specification | Remark |

|---|---|---|---|

| 1 | Welding Process | High Current Mig Welding | |

| 2 | Pole Composition | 1Pole | |

| 3 | Welding Position | 1G | |

| 4 | Applied Wire | ∅3.2mm , ∅4.0mm | |

| 5 | Welding Speed | 180mm/min ~ 500mm/min |