Automation Facilities

GIRTH SEAM OUTSIDE WELDING SYSTEM

Equipment Overview

This system is composed to allow continuous operation from Arc Start to the end of work by applying 3poles SAW technique and high precision Sensing System to the Circumferential Seam Outside welding of the plural-pipe member supplied with inside welding during entire process. In addition, since it consists of a gantry type welding system in which 3Poles Weld Head 2Units are composed in parallel to a Turning Roller 1Set applied with anti-drift system, it is manufactured so that it can outside-weld two Circumferential Seams simultaneously in a plural pipe (composed of 3 single pipes), and an automatic flux spraying and recovery system is also installed in the additionally-installed Manipulator.

Equipment Composition

- Main Column

- Lifting Platform

- Welding Head (3Poles x 2Head)

- 500Kg Wire Reel (6Sets)

- Flux Supply & Recovery Device

- Welding Power Source & Equipment (6Poles)

- 300Ton Transfer Turning Roller

- Anti Drift System

- Control System

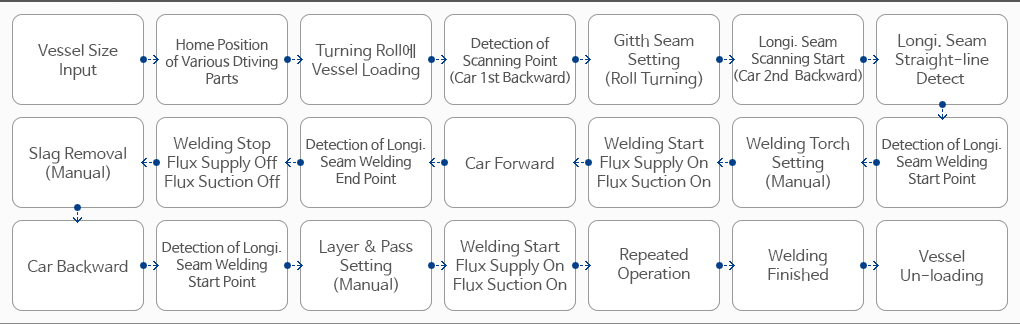

Equipment Operation

Welding Technique

- Submerged Arc Welding : 3Poles x 2Head (Dc + Ac + Ac)

- Welding Position : 1G

- Welding Speed : 1,000mm/min ~ 1,600mm/min