Automation Facilities

- 3POLES-3HEAD BUTT WELDING M/C

- LONGI. FIT-UP & WELDING MACHINE

- 40POLES LONGI. WELDING M/C

- Chemical Single Pipe & Plural Pipe Automatic Line

- LONGI. SEAM INSIDE/OUTSIDE WELDING SYSTEM

- GIRTH SEAM OUTSIDE WELDING SYSTEM

- PIPE INSIDE WELDING SYSTEM

- PIPE OUTSIDE WELDING SYSTEM

- DIAPHRAGM GIRTH WELDING MANIPULATOR

- MOSS LNG TANK 제작용 TILTING JIG

LONGI. SEAM INSIDE/OUTSIDE WELDING SYSTEM

Equipment Overview

This system is intended to improve the production efficiency through automation of inside welding in the single pipe manufacturing process during the whole process and, by applying the 3poles SAW technique and the high precision seam tracking system to Longitudinal Seam Inside welding of the single-pipe member supplied with bending and fit-up, it is designed to allow continuous operation from Arc Start to the end of operation. The basic composition consists of a fixed type Manipulator with welding system and a Turning Roll for weld driving and member support. In addition, the automatic flux spraying and recovery system is composed of Filtering and Heating System for continuous Flux supply, recovery, and the reuse of recovered flux, and continuous welding is possible.

Equipment Composition

- Main Column

- Horizontal Boom

- Welding Head (3Poles)

- 500Kg Wire Reel (3Sets)

- Flux Supply & Recovery Device

- Welding Power Source & Equipment (3Poles)

- 100Ton Turning Roller

- Control System

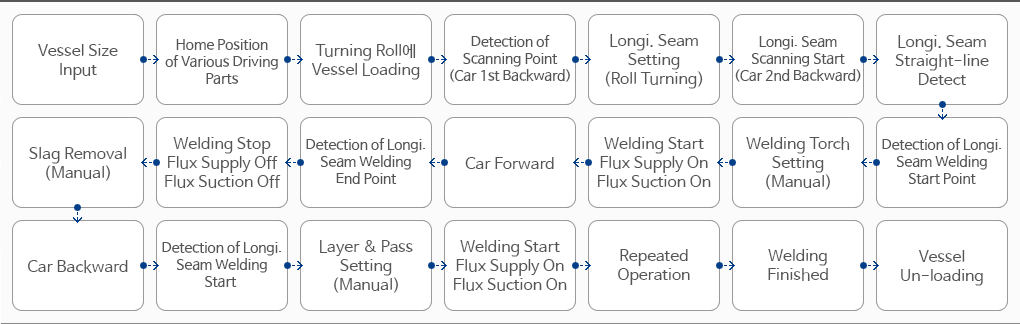

Equipment Operation

Welding Technique

- Submerged Arc Welding : 3Poles x 1Head (Dc + Ac + Ac)

- Welding Position : 1G

- Welding Speed : 1,000mm/min ~ 1,600mm/min