Automation Facilities

PIPE INSIDE WELDING SYSTEM

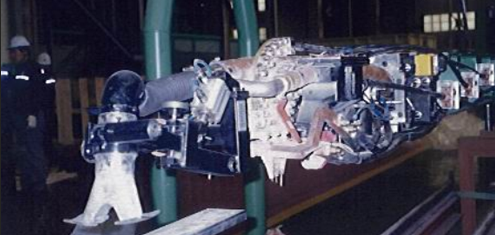

Equipment Overview

This system is an equipment for automatic welding in the longitudinal direction (Longi. Seam) of the inner surface of the steel pipe during the steel pipe manufacturing process of the centralized control type and, by mounting 4-Line 3-electrode Submerged Arc Welding Head and peripherals on the tip of the Manipulator Boom which is installed fixed and used for welding, it makes continuous welding possible from the Arc Start to the end by applying the SAW 3Poles welding technique and the Laser Vision Sensing System for welding seam tracing to the member loaded by the Transfer Car, and also it enables 4Line to be welded at the same time, which can improve the productivity and quality of products.

Equipment Composition

- Welding Boom

- Welding Head (3Poles x 4Lines)

- 500Kg Wire Reel (12Sets)

- Flux Supply &am; Recovery Device (4Lines)

- Laser Vision System (4Lines)

- Welding Power Source & Equipment (3Poles x 4Lines)

- Control System

Welding Technique

- Submerged Arc Welding : 3Poles x 4Head( Curved Torch)

- Welding Position : 1G

- Welding Speed : 300mm/min ~ 3,500mm/min